in pit crushing and conveying wireless

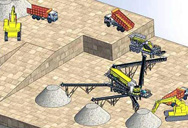

In-pit crushing and conveying technology in open-pit mining

In-Pit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of open-pit mining operations and what is expected to occur in the future. Today, it has become more necessary than ever to reduce the cost of truck

اObtener precio

Comparison of fixed and mobile in-pit crushing and conveying

In-pit crushing and conveying (IPCC) systems (whether fixed, mobile, or semi-mobile) are an alternative to the traditional truck/shovel approach to materials

اObtener precio

OVERWIEW OF IN-PIT CRUSHING CONVEYING TECHNOLOGY

The essence of this paper is to compare and review the various types of IPCC systems, present the advantages and disadvantages among them and in

اObtener precio

In-pit crushing and conveying systems changing the

In light of these challenges, in-pit crushing and conveying (IPCC) is a technology that has grown in popularity since it

اObtener precio

In-Pit Crushing and Conveying (IPCC) - TAKRAF GmbH

In-Pit Crushing and Conveying (IPCC) systems cut truck haulage to a minimum and build operational resilience - they substantially reduce operational expenditure (opex) and provide various other environmental

اObtener precio

(PDF) Review of the in-pit crushing and conveying

In-pit crushing and conveying (IPCC) is an alternative transport system which requires a higher initial investment but gives substantial saving in operating cost. IPCC is the superior technology...

اObtener precio

In Pit Crushing and Conveying Systems - ThyssenKrupp

In Pit Crushing and Conveying Systems - ThyssenKrupp

اObtener precio

In-pit Crushing and Conveying (IPCC) as a driver of reduced

Background In a time where: (a) open pits are getting deeper requiring lower mining cost solutions, and (b) there is increasing pressure on mining companies to

اObtener precio

Motorized Reels for In-Pit Crushing and Conveying Systems

In-pit Crushing and Conveying (IPCC) systems have been around for over 50 years. But due to recent economic circumstances, mining companies have become increasingly

اObtener precio

Industrial Automation in Mining Environments - Cisco

Wireless sensor networks in Refining and Waste Management stages of the mining process covered by the Oil Gas Wireless sensor solution This release of the mining solution does not currently cover the following, but it will be addressed in future releases: Wireless deployments for autonomous vehicles, for example during Extraction

اObtener precio

In-Pit Crushing and Conveying (IPCC) - TAKRAF GmbH

Crushing and conveying - safe, environmentally friendly and efficient. In-Pit Crushing and Conveying (IPCC) systems cut truck haulage to a minimum and build operational resilience - they substantially reduce operational expenditure (opex) and provide various other environmental and safety benefits too. IPCC - an alternative to conventional ...

اObtener precio

Outotec Launches In-Pit Crush and Convey Solutions

Key benefits of Outotec in-pit crushing and conveying technology: Optimal processing with patented SmartStation Up to 30% higher capacity on the same crusher size and 70% reduced downtime with Superior MKIII Primary Gyratory technology Up to 30% power savings with patented Energy Savings Idlers (ESI)

اObtener precio

OVERWIEW OF IN-PIT CRUSHING CONVEYING TECHNOLOGY IN OPEN PIT

In-pit crushing and conveying (IPCC) is an alternative transport system which requires a higher initial investment but gives substantial saving in operating cost. IPCC is the superior technology ...

اObtener precio

In-pit crushing and conveying technology in open-pit mining

In-Pit Crushing and Conveying (IPCC) has gained popularity in the last two decades in the mining sector (Osanloo and Paricheh, 2020), in response to the decreasing ore quality and increasing...

اObtener precio

In-pit crushing and conveying systems changing the way ore is

In light of these challenges, in-pit crushing and conveying (IPCC) is a technology that has grown in popularity since it was first implemented in the 1950s. The purpose of an IPCC system is...

اObtener precio

SRK Publication Risks and Opportunities of Open-Pit Crushing

Category 1 Category 2 Category 3 Category 4. In suitable mining projects, in-pit crushing and conveying (IPCC) can provide operating cost reductions to the tune of 20 - 60% savings, depending on project specifics. For this reason, IPCC systems have been in use around the world for decades. IPCC systems consist of a primary crusher installed in ...

اObtener precio

v117n6a11 In-pit crusher location as a dynamic location

In-pit crusher location as a dynamic location problem by M. Paricheh*, M. Osanloo*, and M. Rahmanpour*!'7904:4 The cost efficiency and high reliability of semi-mobile or combined in-pit crushing-conveying (IPCC) and truck systems, compared to conventional truck-shovel systems alone, make them more attractive for use in modern mining operations.

اObtener precio

In Pit Crushing and Conveying Systems - ThyssenKrupp

In Pit Crushing and Conveying Systems - ThyssenKrupp

اObtener precio

In-Pit Crushing and Conveying (IPCC) - A Tried and Tested

In-pit crushing and conveying (IPCC) could lead the way as a partial or complete substitute for trucks. In 13 of 15 studies undertaken by Sandvik and Snowden, comparing IPCC with truck-optimised pit designs, IPCC generated operating savings ranging from US$0.18 to US$0.82 per tonne moved, compared to trucks. Trucks have higher operating ...

اObtener precio

Haulage systems for open pit mines - 3 main types - GRT

In-pit crushing and conveying IPCC systems consist of the application of a fully mobile, semi-mobile or fixed-in-pit primary crusher, which is coupled to a conveyor system. IPCC systems could lead to the partial or complete substitute for trucks because of their lower operating, maintenance and energy costs for conveyors.

اObtener precio

SURFACE MINING Continuous operations - ABB

This new continuous open pit miningsystem will be the first of its kind in China.The fully mobile in-pit crusher is a newdevelopment from ThyssenKrupp, which, thecompany says, “will be the future for allopen pit mining operations with large outputsworldwide.

اObtener precio

In Pit Crushing and Conveying (IPCC) Systems - bmt

Rio Tinto Clermont Mine in Central Queensland uses an In-Pit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine. The IPCC consists of a fully mobile sizing rig operating in the upper levels of the pit combined with, a ramp conveyor, 2.5km movable pivoting dump conveyor, and a tripper/stacker on ...

اObtener precio

How IPCC technology can support sustainability targets – Worley

In-pit crushing and conveying: a flexible solution for sustainable mining. Today, most mines depend on large mining trucks to haul material out of the mining pit to crushing and processing plants. “In-pit crushing and conveying (IPCC) is a direct alternative to this approach,” explains Russell. “It involves crushing ore and waste material ...

اObtener precio

In-Pit Crushing and Conveying (IPCC) - TAKRAF GmbH

Crushing and conveying - safe, environmentally friendly and efficient. In-Pit Crushing and Conveying (IPCC) systems cut truck haulage to a minimum and build operational resilience - they substantially reduce

اObtener precio

In-pit crushing and conveying technology in open-pit mining

In-Pit Crushing and Conveying (IPCC) has gained popularity in the last two decades in the mining sector (Osanloo and Paricheh, 2020), in response to the decreasing ore quality and increasing...

اObtener precio

In Pit Crushing and Conveying (IPCC) Systems

Rio Tinto Clermont Mine in Central Queensland uses an In-Pit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine. The IPCC consists of a fully mobile sizing rig

اObtener precio

OVERWIEW OF IN-PIT CRUSHING CONVEYING TECHNOLOGY IN OPEN PIT

The essence of this paper is to compare and review the various types of IPCC systems, present the advantages and disadvantages among them and in comparison with other types of haulage, as well as...

اObtener precio

SRK Publication Risks and Opportunities of Open-Pit Crushing

IPCC systems consist of a primary crusher installed in-pit, close to the active mining areas. The crusher is used to crush mined material to a suitable size for transportation via a downstream conveyor system. The conveyor then transports the

اObtener precio

v117n6a11 In-pit crusher location as a dynamic location

In-pit crushers can be classified as: Semi-mobile operation (known as discontinuous systems): this involves a primary crushing unit inside the pit together with a shovel-truck system. After crushing, the materials is hauled by conveyor to the predetermined destination (processing plant or waste dump).

اObtener precio

In Pit Crushing and Conveying Systems - ThyssenKrupp

In Pit Crushing and Conveying Systems - ThyssenKrupp

اObtener precio

In-pit crusher location as a dynamic location problem

The conveying distance (or conveying costs) from in-pit crusher to an ex-pit destination is another factor that affects haulage costs. With the lower costs of conveyor transport compared to trucking, the in-pit crusher can

اObtener precio

SURFACE MINING Continuous operations - ABB

This new continuous open pit miningsystem will be the first of its kind in China.The fully mobile in-pit crusher is a newdevelopment from ThyssenKrupp, which, thecompany says, “will be the future for allopen pit mining operations with large outputsworldwide.

اObtener precio

In-Pit Crushing and Conveying (IPCC) - A Tried and Tested

In-pit crushing and conveying (IPCC) could lead the way as a partial or complete substitute for trucks. In 13 of 15 studies undertaken by Sandvik and Snowden, comparing IPCC with truck-optimised pit designs, IPCC generated operating savings ranging from US$0.18 to US$0.82 per tonne moved, compared to trucks. Trucks have higher operating ...

اObtener precio

Feasibility of in-Pit Crushing and Conveying of Waste Rock at Mt ...

A semi-mobile in-pit crushing and conveying system was found to be most suited to Mt Whaleback conditions. The East Pit was selected as the best location based on the analysis of haulage profiles measured on long term incremental mine plans. A capacity of 22 million tonnes per year was considered achievable by the proven technology currently ...

اObtener precio

How IPCC technology can support sustainability targets – Worley

In-pit crushing and conveying: a flexible solution for sustainable mining Today, most mines depend on large mining trucks to haul material out of the mining pit to crushing and processing plants. “In-pit crushing and conveying (IPCC) is a direct alternative to this approach,” explains Russell.

اObtener precio

Belt Conveyors for mining applications - TAKRAF GmbH

Open-pit or underground applications and In Pit Crushing Conveying (IPCC) Our conveyors are specifically designed for their application and each project’s unique requirements covering a wide range of commodities and capacities. TAKRAF conveyor systems are employed globally from open-pit to underground mines where they

اObtener precio

How to Exit Conveyor from an Open-Pit Mine: A Theoretical

Tutton, D., Streck, W.: The application of in-pit crushing and conveying in large hard rock open pit mines in Niagara-on-the-Lake. In: Mining Magazine Congress (2009) Google Scholar Koehler, F.: In-pit crushing system the future mining option. In: Twelfth International Symposium on Mine Planning and Equipment Selection (2003)

اObtener precioMas noticias

- origin of iron ores in singhbhum mayurbanj region

- trituradora giratoria fuller traylor

- chancadoras de Minerales Metálicos mineral de cobre de la máquina trituradora

- ecuador molino martillo

- planta trituradora sobre ...

- abertura del cono planta trituradoras

- molinos de s de cobre economicos

- bentonite crushing machine cost india

- pg trituradora rodillos

- portable crusher dust control

- areia areia molho de quartzo areia

- oferta de empleos en plantas de trituracion en puerto ordaz

- melhor maquina britador de pedra no brasil

- trituradora de cono usado para la venta en miami

- Beneficiation Of Copper Ore

- De arena móvil de chancado de la planta

- imagenes sobre el circuito productivo del papel

- compro chancadora de piedra zaranda vibradora incluyendo faja transportadorasaranda

- Impacto Trituradoras Equipos

- proceso de seleccion

- trituradoras de cono del sistema de lavado

- pantalla de roca y dispositivo alimentador

- de fabricación de equipos industriales en trituradoras de india

- 1 CLASIFICACIÓN DE LOS MATERIALES 1 1

- arena chancadoras de mandibu

- tamil nadu política de gobierno de la trituradora

- stone puzzolana crushing equipment in india

- China móvil concreto lotes de plantasde hormigón planta de mezcla

- que es el cono de un quebrador de piedra

- usos de mineral de manganeso